Multi-Block Structured Parts

TrueGrid® supports structured multi-block meshes. Multi-block means that the block topology can be made from multiply connected blocks. Each block is composed of 3D hexahedral, 2D quadrilateral, and 1D linear or quadratic elements arranged in rows, columns, and layers. These blocks can be moved, deleted, replicated or glued to other blocks or parts. The multi-block structure gives users more control over the design of their mesh, ensures that quality is maintained throughout their design, and achieves these results with minimal effort.

Proper Topology Produces High Quality

The multi-block structure gives the user flexibility in the design of their mesh so that the highest quality can be acheived. The single-block structure lacks this flexibility and control so even the simplest geometry can have bad results.

2D Example

A simple 2D example is used to illustrate the importantance of a multi-block structure to build proper topology. |

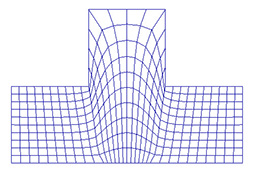

Single-Block TopologyA single-block is used to construct a simple mesh. Using one block to construct this mesh, the mesh lines are forced to conform to the geometry giving the mesh a distorted form and bad elements. |

|

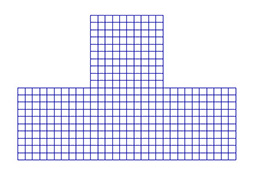

Multi-Block TopologyA multi-block topology is used to build a mesh for the same geometry. This mesh was built in TrueGrid® starting from 6 blocks and deleting the top 2 corner blocks to achieve a mesh with perfect aspect ratio and no bad elements. |

3D Example

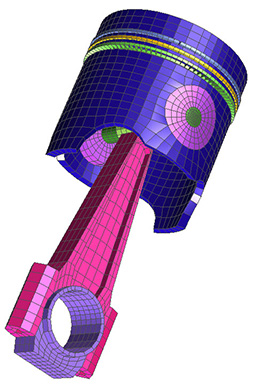

Users have control over the design by being able to choose their own topology. The multi-block structure makes it possible for TrueGrid® to perform classical mathematic functions behind the scenes to ensure a quality mesh throughout the design. Choosing the appropriate topology makes it easier to acheive high quality for complex geometry. Here a 3D example is used to illustrate the power of the multi-block structure.

|

Multi-Block Mesh of a Piston and RodThis piston and rod model was created with relative ease from a multi-block structure. The design of the topology was chosen to acheive the best quality for this mesh.View Piston Command File |

|

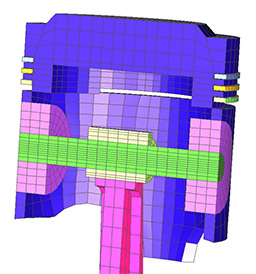

Piston Cut in HalfSlicing the piston in half, we are able to see that the part maintains the quality all the way through the mesh. This would not be possible without the multi-block structured design. |

Avoid Duplication of Effort and Save Time

With the multi-block structure, you start out with blocks already connected. This makes building a part in TrueGrid® faster because you only need to shape regions of the mesh in one step, thus eliminating duplication of effort.

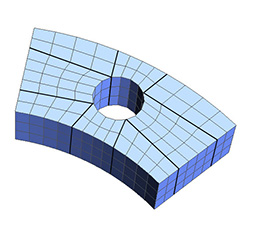

|

Mesh With HoleThis part was created in TrueGrid® using a multi-block structure of 9 blocks. The center block was deleted and the the faces projected. This part was made in 5 easy steps with TrueGrid®. If you were using a single block structure you would have to shape 8 separate blocks to acheive this mesh. |

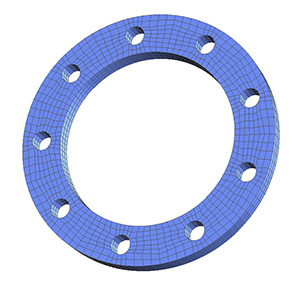

|

Completed Ring With HolesTo finish this mesh in TrueGrid® the part was replicated using one command to form the entire ring. The multi-block method allowed for the replication of one part, glued these parts together to acheive a completely different model. All of this with trivial commands. View TrueGrid® Command File for Ring Mesh |